| . |

| . |

| . |

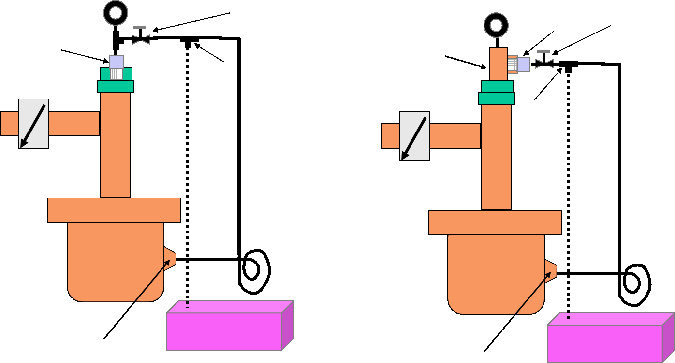

See diagrams below for several options on how to hook up the SFR flowline. Many operators prefer to hook up the Sidestream Flush Restrictor (SFR) on the one inch outlet side of the pump tee. A one inch tee is

normally attached to the pump tee with the following installation:

(1) 1 x ¼” bushing (with brass or red plastic filter) screwed into 1” tee.

(2) Bushing is recommended to be above a horizontal inlet position

(3) A short ¼” nipple screwed into bushing

(4) A ¼” ball valve (to allow chemical changes, etc.) screwed into nipple. Not required.

(5) A ¼ x ¼ x ¼ chemical tee screwed into

a. short nipple (step #3) or

b. made up into ball valve from step #4 (with another nipple)

(6) The Hydraulic coiled Restriction hose (for pressure drop and restricting rate) made up to the chemical tee in step #5, no adjustment necessary.

Some prefer to screw the ¼ connection into the chemical tee with the JIC connection screwed into a 2x 1/4 bushing connected to the casing inlet.

This allows one to disconnect from the casing and flow test the SFR into a bucket (if safe).

(7) Screw JIC connection into a 2 x 1/4 bushing connected to the casing inlet.

(8) The Chemical line from the chemical pump is made up to the ¼ x ¼ x ¼ chemical tee attached in step 5.

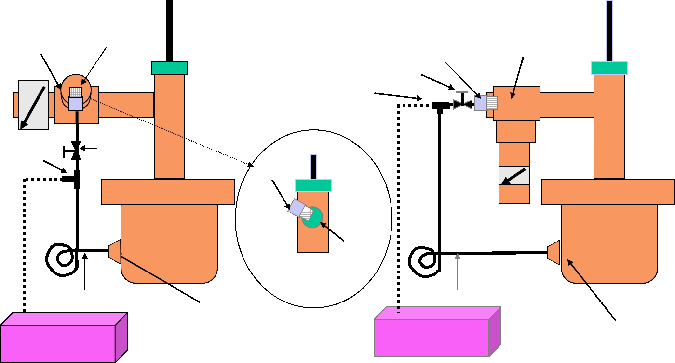

normally attached to the pump tee with the following installation:

(1) 1 x ¼” bushing (with brass or red plastic filter) screwed into 1” tee.

(2) Bushing is recommended to be above a horizontal inlet position

(3) A short ¼” nipple screwed into bushing

(4) A ¼” ball valve (to allow chemical changes, etc.) screwed into nipple. Not required.

(5) A ¼ x ¼ x ¼ chemical tee screwed into

a. short nipple (step #3) or

b. made up into ball valve from step #4 (with another nipple)

(6) The Hydraulic coiled Restriction hose (for pressure drop and restricting rate) made up to the chemical tee in step #5, no adjustment necessary.

Some prefer to screw the ¼ connection into the chemical tee with the JIC connection screwed into a 2x 1/4 bushing connected to the casing inlet.

This allows one to disconnect from the casing and flow test the SFR into a bucket (if safe).

(7) Screw JIC connection into a 2 x 1/4 bushing connected to the casing inlet.

(8) The Chemical line from the chemical pump is made up to the ¼ x ¼ x ¼ chemical tee attached in step 5.

Note 1: Filter bushing is usually located between horizontal and vertical (on top of flowline tee) and not on bottom of flowline

(top half of line or tee).

Note 2: Quarter inch valve is normally fully open, used to allow changing SSF line.

Note 3: One can let the casing pressure buildup by SI of casing and then open casing with pressure higher than tubing to

blow off filter if it gets plugged.

Note 4: Ensure all connections and piping are rated for maximum operational pressures anticipated or encountered.

Note 5: Many other configurations are possible and operator is responsible for determining the design that best meets their

needs.

(top half of line or tee).

Note 2: Quarter inch valve is normally fully open, used to allow changing SSF line.

Note 3: One can let the casing pressure buildup by SI of casing and then open casing with pressure higher than tubing to

blow off filter if it gets plugged.

Note 4: Ensure all connections and piping are rated for maximum operational pressures anticipated or encountered.

Note 5: Many other configurations are possible and operator is responsible for determining the design that best meets their

needs.

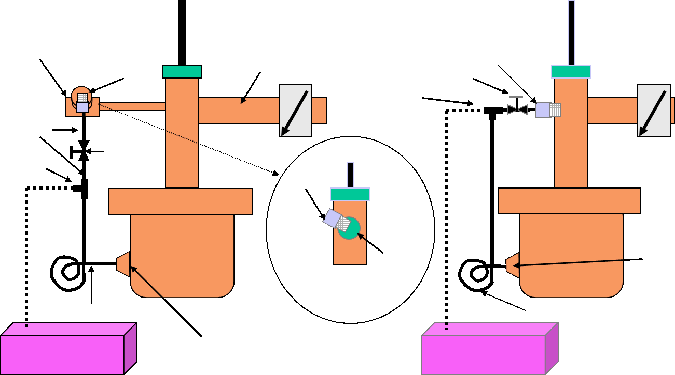

Note 1: Quarter inch valve is normally fully open, used to allow changing of SSF line

Note 2: One can let the casing pressure buildup by SI of casing and then open casing with pressure higher than tubing to

blow off filter if it gets plugged.

Note 3: Ensure all connections and piping are rated for maximum operational pressures anticipated or encountered.

Note 4: Wells producing sand may prefer one inch tee configuration on above right to prevent filter from being sand blasted.

Note 5: Many other configurations are possible and operator is responsible for determining the design that best meets their

needs.

Note 2: One can let the casing pressure buildup by SI of casing and then open casing with pressure higher than tubing to

blow off filter if it gets plugged.

Note 3: Ensure all connections and piping are rated for maximum operational pressures anticipated or encountered.

Note 4: Wells producing sand may prefer one inch tee configuration on above right to prevent filter from being sand blasted.

Note 5: Many other configurations are possible and operator is responsible for determining the design that best meets their

needs.

Note 1: Quarter inch valve is normally fully open, used to allow changing of SSF line

Note 2: One can let the casing pressure buildup by SI of casing and then open casing with pressure higher than tubing to

Note 3: Ensure all connections and piping are rated for maximum operational pressures anticipated or encountered.

Note 4: Wells producing sand may prefer one inch tee configuration on above right to prevent filter from being sand blasted.

Note 5: Many other configurations are possible and operator is responsible for determining the design that best meets their

needs.

Note 2: One can let the casing pressure buildup by SI of casing and then open casing with pressure higher than tubing to

Note 3: Ensure all connections and piping are rated for maximum operational pressures anticipated or encountered.

Note 4: Wells producing sand may prefer one inch tee configuration on above right to prevent filter from being sand blasted.

Note 5: Many other configurations are possible and operator is responsible for determining the design that best meets their

needs.

| Flowline Side Installation |

| Installation for Submersible Pumped Wells |

| Installation on 1" Pump Tee |

| Sidestream Flush Restrictor Installation |

| Preferred |

| Alternate |

1" Tee

| Filter Bushing |

| 1/4" Nipple |

1/4" Valve

1/4" Tee

| 2" or 3" Flowline |

| Filter Bushing |

1" Tee

View towards 1" tee

| Chemical |

| Chemical |

| Casing Valve/Inlet (normally a tee and 2" valve) |

| SSF Restriction Line |

| Filter Bushing |

1/4" Valve

1/4" Tee

| Casing Valve/Inlet (normally a tee and 2" valve) |

| Filter Bushing |

1/4" Tee

1/4" Valve

| Casing Valve/Inlet (normally a tee and 2" valve) |

| Chemical |

| Casing Valve/Inlet (normally a tee and 2" valve) |

| Chemical |

1/4" Tee

| Filter Bushing |

1/4" Valve

1" Tee

| 2" or 3" Flowline |

Pressure Gauge

Pressure Gauge

| Flowline Tee |

| Filter Bushing |

1/4" Tee

1/4" Valve

| SSF Restriction Line |

| Chemical |

| Chemical |

| Casing Valve/Inlet (normally a tee and 2" valve) |

| Casing Valve/Inlet (normally a tee and 2" valve) |

View towards 1" tee

1" Tee

| Filter Bushing |

1/4" Tee

1/4" Valve

| Filter Bushing |

| Flowline Tee |

| SSF Restriction Line |

| . |

| . |

| . |

| . |

| . |

| . |

| . |

| Engineering: |

| Sales: |