| . |

| . |

| . |

| . |

| . |

| . |

| . |

| . |

| . |

| . |

PROBLEM:

Corrosion holes on 20% of

tubing

CAUSE:

Corrosion inhibitor worn off

by rod string ( boxes, guides,

or body)

REMEDY (tubing corrosion):

1) Manual tubing rotator

2) Polyethylene-lined tubing

REMEDY (rod corrosion):

1) Rod rotators

2) Spray metal alloy boxes

Corrosion holes on 20% of

tubing

CAUSE:

Corrosion inhibitor worn off

by rod string ( boxes, guides,

or body)

REMEDY (tubing corrosion):

1) Manual tubing rotator

2) Polyethylene-lined tubing

REMEDY (rod corrosion):

1) Rod rotators

2) Spray metal alloy boxes

1) OXYGEN

Large, shallow, flat bottomed pitting with pit edges gradually sloping

and running into each other

2) HYDROGEN SULFIDE

Pits small and cone shaped with steep sloping sides and round

edges on metal surfaces. Generally pits are not connected and may

contain wide, sharp fatigue cracks. Surface may have iron sulfide

scale (black, sticky, and rotten egg odor.

3) CARBON DIOXIDE

Round-bottomed pitting with sharp sides and normally connected

with other pits. Surface may have iron carbonate scale (gray).

Large, shallow, flat bottomed pitting with pit edges gradually sloping

and running into each other

2) HYDROGEN SULFIDE

Pits small and cone shaped with steep sloping sides and round

edges on metal surfaces. Generally pits are not connected and may

contain wide, sharp fatigue cracks. Surface may have iron sulfide

scale (black, sticky, and rotten egg odor.

3) CARBON DIOXIDE

Round-bottomed pitting with sharp sides and normally connected

with other pits. Surface may have iron carbonate scale (gray).

| PROBLEM: External corrosion CAUSE: Tubing wear against casing, wiping off inhibitors REMEDY: 1) Tubing anchor 2) Manual tubing rotator |

Note: casing vent lines, rubber packing, etc. can help stop oxygen entry

PROBLEM:

Corrosion pitting around entire circumference of tubing or rods

CAUSE:

Poor corrosion inhibitor film (if any)

REMEDY:

1) Change chemical program (type, frequency, circulation time)

2) Minimize elements (oxygen, bacteria, etc.)

3) Fiberglass tubing/rods

4) Manual tubing rotator w/ chemical

Corrosion pitting around entire circumference of tubing or rods

CAUSE:

Poor corrosion inhibitor film (if any)

REMEDY:

1) Change chemical program (type, frequency, circulation time)

2) Minimize elements (oxygen, bacteria, etc.)

3) Fiberglass tubing/rods

4) Manual tubing rotator w/ chemical

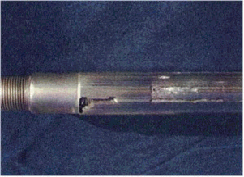

PROBLEM:

Tubing plits

CAUSE:

Rod wear against tubing

REMEDY:

1) Tubing Rotator

2) Polyethylene-lined tubing

3) Rod guides

4) Slow SPM

5) Sinker bars if wear near

bottom

Tubing plits

CAUSE:

Rod wear against tubing

REMEDY:

1) Tubing Rotator

2) Polyethylene-lined tubing

3) Rod guides

4) Slow SPM

5) Sinker bars if wear near

bottom

| COMMON CORROSION TYPES |

| Rod Pumping Failure Analysis |

| . |

| . |

| . |

| . |

| . |

| . |

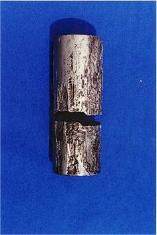

PROBLEM:

Rod box or body failures due to corrosion around

all of the tubing circumference

CAUSE:

Inadequate or no corrosion inhibition program

REMEDY:

1) Spray metal alloy rod boxes for box failures

2) Improve or implement chemical program (type,

frequency, circulation time) for boxes and bodies

Rod box or body failures due to corrosion around

all of the tubing circumference

CAUSE:

Inadequate or no corrosion inhibition program

REMEDY:

1) Spray metal alloy rod boxes for box failures

2) Improve or implement chemical program (type,

frequency, circulation time) for boxes and bodies

PROBLEM:

Pin breaks due to

make-up

CAUSE:

Over-tightened or

under-tightened connections

REMEDY:

Proper Make-up

Pin breaks due to

make-up

CAUSE:

Over-tightened or

under-tightened connections

REMEDY:

Proper Make-up

PROBLEM:

Rod Body Failures due to fatigue

CAUSE:

Tension or compression failures as indicated by horizontal lines on the rod body

Note: compression usually has cracks on one side, while tension usually has lines

around the entire circumference

REMEDY:

1) Redesign to reduce rod stresses (SPM, pump size, sinker bars, stroke length, etc.

2) Wheeled rod guides reduce friction on up and down stroke (helps tension &

compression)

3) Remove some rod guides that may be increasing stress on rods

Rod Body Failures due to fatigue

CAUSE:

Tension or compression failures as indicated by horizontal lines on the rod body

Note: compression usually has cracks on one side, while tension usually has lines

around the entire circumference

REMEDY:

1) Redesign to reduce rod stresses (SPM, pump size, sinker bars, stroke length, etc.

2) Wheeled rod guides reduce friction on up and down stroke (helps tension &

compression)

3) Remove some rod guides that may be increasing stress on rods

| . |

| . |

| . |

| . |

PROBLEM:

Worn pumps

CAUSE:

Wear over time or solid abrasions (sand, scale or pump

chrome after acid jobs)

REMEDY:

1) Mud anchors

2) Raise pump depth

3) change pump type

4) tubing rotation should spread wear/abrasion around pump

to extend life

5) Gravel packs, etc.

Worn pumps

CAUSE:

Wear over time or solid abrasions (sand, scale or pump

chrome after acid jobs)

REMEDY:

1) Mud anchors

2) Raise pump depth

3) change pump type

4) tubing rotation should spread wear/abrasion around pump

to extend life

5) Gravel packs, etc.

PROBLEM:

Rod box or rod body failures due to wear

CAUSE:

Wear or "corrosion due to wear wiping

off corrosion inhibitor" on one side of the

rod box or rod body

SOLUTION:

(1) Spray metal alloy rod boxes for wear

(2) rod rotator for box or rod body wear

(3) rod guides

(4) continuous rods

Rod box or rod body failures due to wear

CAUSE:

Wear or "corrosion due to wear wiping

off corrosion inhibitor" on one side of the

rod box or rod body

SOLUTION:

(1) Spray metal alloy rod boxes for wear

(2) rod rotator for box or rod body wear

(3) rod guides

(4) continuous rods

| . |

| . |

| . |

| . |

| . |

| . |

| . |

| Engineering: |

| Sales: |

| . |

| Downloadable version: Failure Analysis.pdf |